General Information

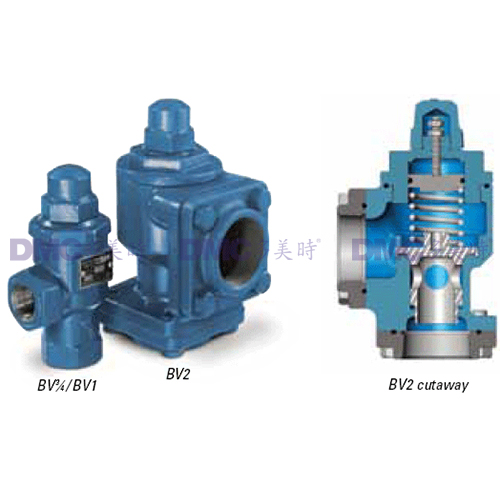

Blackmer differential bypass valves are designed to protect pumps and system components from excessive pressure damage, and no LP gas pump installation is complete without one. Blackmer offers five different models that provide full-flow pressure control to 250 U.S. gpm (946 lpm) at 120 psid (8.27 Bar). Installation is easy with NPT tapped ports in sizes from ¾" to 2". All models are suitable for both LP gas and anhydrous.

Operation

Blackmer valves provide exceptionally close pressure control, even under widely varying bypass flow conditions. The performance curve in Figure 4 shows how a Blackmer valve maintains a virtually constant pressure of 100 psi (6.89 Bar) even as the volume being bypassed rises from 10 gpm to 100 gpm (38-378 lpm). Although the curve is that of a BV1½" valve, the precision it demonstrates is typical of any Blackmer valve.

Blackmer bypass valves have no small, easily plugged, sensing passages; and with only two moving parts, their operation is simple and reliable. They open precisely at the preset spring pressure, and they close smoothly and quietly, thanks to a patented dash-pot design. As shown in Figure 5, a small chamber in the valve stem fills with liquid when the valve opens. This liquid then provides a hydraulic cushion preventing the valve from slamming shut if pressure is suddenly released. It also minimizes chatter and valve seat wear when pressures hover around the crucial limit.

Blackmer differential bypass valves are designed to protect pumps and system components from excessive pressure damage, and no LP gas pump installation is complete without one. Blackmer offers five different models that provide full-flow pressure control to 250 U.S. gpm (946 lpm) at 120 psid (8.27 Bar). Installation is easy with NPT tapped ports in sizes from ¾" to 2". All models are suitable for both LP gas and anhydrous ammonia service.